Verified hydropower source

Production powered by Guangyuan's green hydroelectric grid. Certified green-electricity aluminium product evaluation for 110,000 t molten aluminium on file.

Supplier profile for Germany & Europe

Guangyuan Huabo produces high-purity aluminium ingots using proprietary segregation technology co-developed with Shanghai Jiao Tong University. Powered 100% by Guangyuan's green hydropower, with full EU compliance documentation.

Core differentiation

Our facility in Guangyuan, Sichuan is powered entirely by the region's abundant hydroelectric resources. This is not a carbon offset claim, it is direct green electricity supply, verified by an independent evaluation covering 110,000 tons of molten aluminium.

Production powered by Guangyuan's green hydroelectric grid. Certified green-electricity aluminium product evaluation for 110,000 t molten aluminium on file.

Provide your sustainability team with a documented low-carbon aluminium source. Full evidence package for supplier pre-qualification and internal reporting.

Hydropower-based production means significantly lower embedded carbon vs. coal-powered smelters. Advantageous positioning as EU CBAM requirements tighten.

Low-carbon procurement brief

Proprietary process

Directional solidification purification by controlling crystal growth morphology. Multi-stage segregation achieves purity grades from 3N2 to 4N5.

3N purity electrolytic primary aluminium (99.9%) from hydropower smelters in Guangyuan region.

25t melting furnace for refining and impurity removal. Online filtration system followed by crucible loading.

Horizontal continuous rotation segregation. Produces 3N2 (99.92%) and 4N (99.99%) purity aluminium.

Second-pass purification achieves 4N3 (99.993%) and 4N5 (99.995%) ultra-high purity grades.

Cast into 8-20 kg standard ingots. Each batch undergoes chemical composition analysis before release.

Coded and packaged per customer specification. Export coordination with Germany-based support.

Process jointly developed with Shanghai Jiao Tong University. Directional solidification purification equipment designed for controlling crystal growth morphology. Pilot completed in Gongyi, now in full industrial production in Guangyuan.

Currently expanding to 40 additional segregation furnaces, 3 new pretreatment melting furnaces, plus upgraded power distribution and cooling systems. Target: 30,000 t/year full capacity.

Core portfolio

Produced via segregation purification. Standard ingot weight: 8-20 kg. Custom specifications available.

| Grade | Al % | Si | Fe | Cu | Mn | Mg | Zn | Ga | Purity |

|---|---|---|---|---|---|---|---|---|---|

| 3N2 | 99.9226 | 0.0200 | 0.0261 | 0 | 0.0006 | 0.0004 | 0.0086 | 0.0091 | ≥99.90% |

| 3N5 | 99.9562 | 0.0096 | 0.0128 | 0 | 0.0011 | 0.0007 | 0.0045 | 0.0072 | ≥99.95% |

| 3N8 | 99.9847 | 0.0032 | 0.0021 | 0 | 0.0002 | 0.0002 | 0.0035 | 0.0024 | ≥99.98% |

| 4N | 99.9936 | 0.0015 | 0.0011 | 0 | 0.0002 | 0.0002 | 0.0008 | 0.0014 | ≥99.99% |

Chemical composition in % by weight. Production standard: YS/T665-2018. All values are typical batch results.

Core product. Grades 3N2 through 4N via segregation purification. Standard 8-20 kg ingots for electronics, optics, semiconductor and specialty alloy applications.

3N2 / 3N5 / 3N8 / 4N99.92%-99.995% purity remolten ingots. 8 kg standard blocks. Annual cast capacity 5,000 t. Suitable for downstream alloy production and casting workshops.

5,000 t/year cast capacityIngot weight, composition targets and packaging configured to your production requirements. Contact our Germany representative for technical discussion.

Configured to customer specProduction facility

58 employees including 16 professional technical staff. ISO 9001 and ISO 45001 certified operations.

Click any image to enlarge and browse.

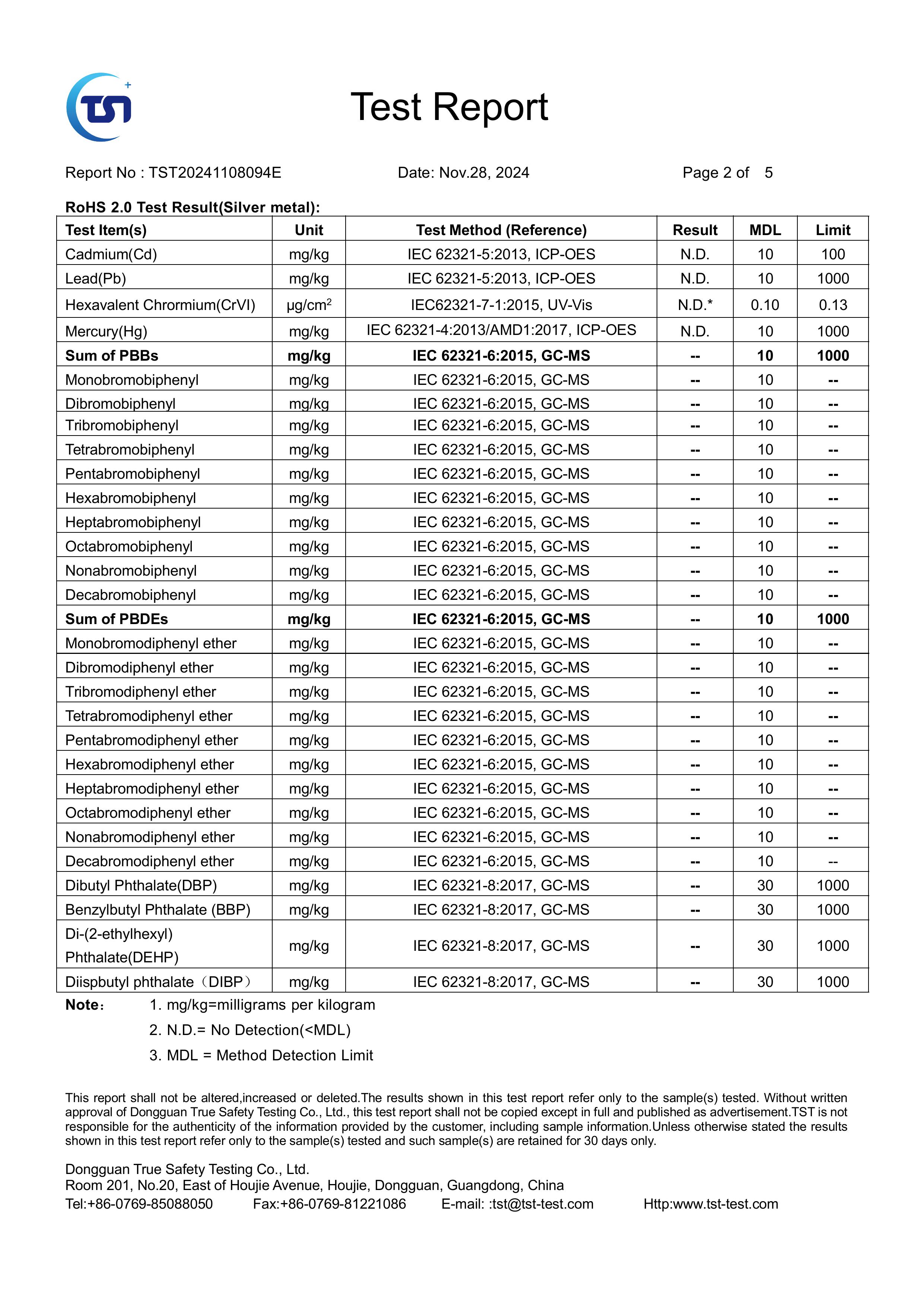

Compliance evidence

All certificates and test reports available for supplier pre-qualification.

Independent testing per IEC 62321 standards. Cadmium, Lead, Mercury, Hexavalent Chromium, PBBs, PBDEs, DBP, BBP, DEHP, DIBP: all below method detection limits. Reports available in Chinese (TST20241108094C) and English (TST20241108094E).

Certificate no. 16423Q30182R0S. Covers aluminium smelting and product quality control. Valid to 2026-03-02.

Certificate no. W16423S30019R0S. Occupational health and safety management system. Valid to 2026-03-02.

Environmental management certification for production operations. Documentation available on request.

Independent evaluation covering 110,000 t molten aluminium scope. Confirms green hydropower energy source for production.

Recognized as small-medium sized innovative enterprise by Guangyuan City. Proprietary segregation technology.

Germany sales point

Technical specifications, commercial terms and logistics coordinated through your Germany-based representative.

Felix Zhao

Mobile: +004915906479598

E-Mail: contact@wffuture.de

Typical response within one business day for qualified inquiries.